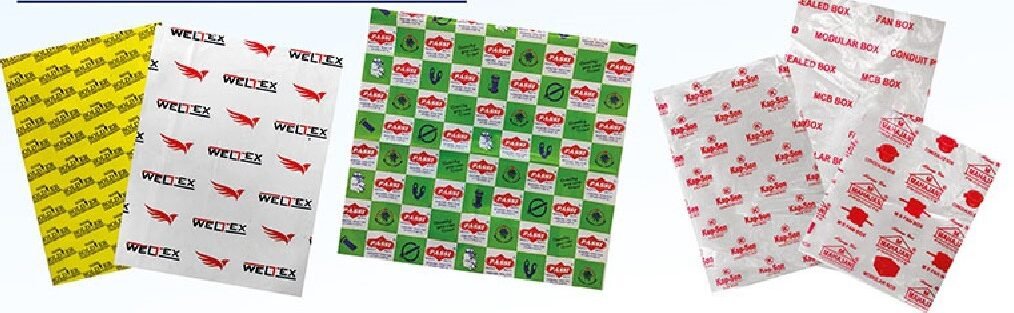

Multicolour Printed Bags/Rolls

Multicolour Printed Bags/Rolls

LDPE (Low-Density Polyethylene) multi-colour printed bags are commonly used for packaging, retail, promotional, and ecommerce purposes due to their durability, flexibility, and cost-effectiveness. These bags can be custom printed with vibrant, multi-colour designs to enhance brand visibility and attract Customers. Below are the key specifications and options when considering LDP E multi-colour printed bags:

MATERIAL

- Type : LDPE (Low-Density Polyethylene) is a lightweight, flexible plastic material known for its toughness and moistureresistance. It' s ideal for making bags that need to handle light to moderate weights and protect the contents from dust, dirt , and water.

- Thickness: LDPE bags are typically available in a range of thicknesses measured in microns (pm), with the most common range being 30 to 100 microns (0.03mm to 0.1mm). For lightweight retail bags, a 40-60 micron thickness is common. Heavier-duty bags may use a thickness Of 80-100 microns.

- Finish: LDPE bags can be manufactured with a glossy or matte finish, depending on the desired 100k, Glossy finishes are more commonly used for retail, while matte finishes may be preferred for more subtle or high-end appearances.

PRINTING

- Gravure Printing: This is another option for high-quality printing, especially for large volumes, but it requires high initial setup costs and is more suited for longer runs.

- FuIl-Colour (CMYK): Flexo and gravure printing techniques allow full-colour prints, where designs can use a wide s pectrum of co to create intricate patterns, logos, or i mages.

- Pantone Matching: If exact colour reproduction is critical, you can specify Pantone colours for consistency across production runs.

- Print Area: LDPE bags can be printed on the front. back, or both sides. with coverage extending up to the edges of the bag. The print area size will depend on the bag's dimensions and the number of colours used.

- Print Quality: The print resolution wiIl vary depending on the printing method.

BAG TYPES A SIZES

LDPE bags can be made in various styles to suit different applications:

- Custom Sizes: LDPE bags can be custom-sized to suit specific packaging needs.

- Ventilation Holes: For items that require air circulation (such as fresh produce), bags may feature small perforations or holes.

CUSTOMIZATION OPTIONS

- Logo & Branding: LDPE bags are commonly used for branding and marketing purposes, with logos, slogans, and artwork printed in multiple colours.

- Custom Prints: You can Create intricate designs, graphics, or even full-colour artwork on LDPE bags, providing great visual appeal for your brand.

- Spot UV : Special gloss treatment can be added to logos or designs for a shiny, eye-catching effect.

PRODUCTION & LEAD TIME

- Minimum Order Quantities (MOQ): Custom LDPE printed bags typically require a minimum order of 500 to 1,000 units, depending on the bag type and pinter.